A first test case - heat diffusion

What do we need?

case files

a mesh

boundary/initial conditions

a solver

simulations controls (time step, run time, etc.)

post-processing

Theory

The first case is the flange case from OpenFOAM tutorials, which illustrates how to solve for 3-D heat conduction in a complex-shaped solid. The equation we will be solving is the transient heat diffusion, a laplacian partial differential equation (PDE) that is here written for the simplfied case of constant properties (Eqn. equation (3)). The equation is based on plugging Fourier’s law (Eqn. equation (1)) into a general energy conservation equation (Eqn. equation (2))

Here \(\rho\) is density, \(C_{cp}\) the specific heat, \(\lambda_r\) the heat conduction coefficient, and \(D=\frac{\lambda_r}{\rho C_{cp}}\) the thermal diffusivity.

Prepare case files

Our first case is the flange case from the OpenFoam tutorials, which illustrates how to solve for 3-D heat conduction in a complex-shaped solid.

Tip

It is good practice to never change the original tutorials, which reside in $FOAM_TUTORIALS but to always make a copy to your working directory.

To get started, just copy the whole case into your shared working directory (probably $HOME/HydrothermalFoam_runs). You need to do this within the docker container (your right-hand shell in Visual Studio Code if you followed the recommended setup). Cd into your shared folder and type this:

cd $HOME/HydrothermalFoam_runs

cp -rf $FOAM_TUTORIALS/basic/laplacianFoam/flange .

An OpenFoam case consist of a certain directory structure, which contains text files that control the case. The tree structure of flange case is shown in Listing 1.

1.

2├── 0

3│ └── T

4├── Allclean

5├── Allrun

6├── constant

7│ └── transportProperties

8├── flange.ans

9└── system

10 ├── controlDict

11 ├── fvSchemes

12 └── fvSolution

The 0 directory contains all initial and boundary conditions, the system folder contains all controlling parameter files, and the constant folder contains constant properties like the mesh - which we will create next.

Mesh generation

The mesh of flange case is prepared as Ansys format (see line 8 of Listing 1), you can use OpenFOAM mesh convert utility of ansysToFoam to convert the ansys format to OpenFOAM format, the command is shown below,

ansysToFoam flange.ans -scale 0.001

The -scale option is used to set scale factor of the whole mesh.

Again, you can use command of tree to explore what changes in the case folder, you can get something like Listing 2, please notice the new files emphasized in the lines 7-13.

1.

2├── 0

3│ └── T

4├── Allclean

5├── Allrun

6├── constant

7│ ├── polyMesh

8│ │ ├── boundary

9│ │ ├── faceZones

10│ │ ├── faces

11│ │ ├── neighbour

12│ │ ├── owner

13│ │ └── points

14│ └── transportProperties

15├── flange.ans

16└── system

17 ├── controlDict

18 ├── fvSchemes

19 └── fvSolution

After converting the mesh, you can use Paraview to visualize the mesh,

touch a.foam

paraview a.foam

Note

touch a.foam means create a empty file named a.foam. You might might have the touch command in windows; then create the empty file inside the docker shell.

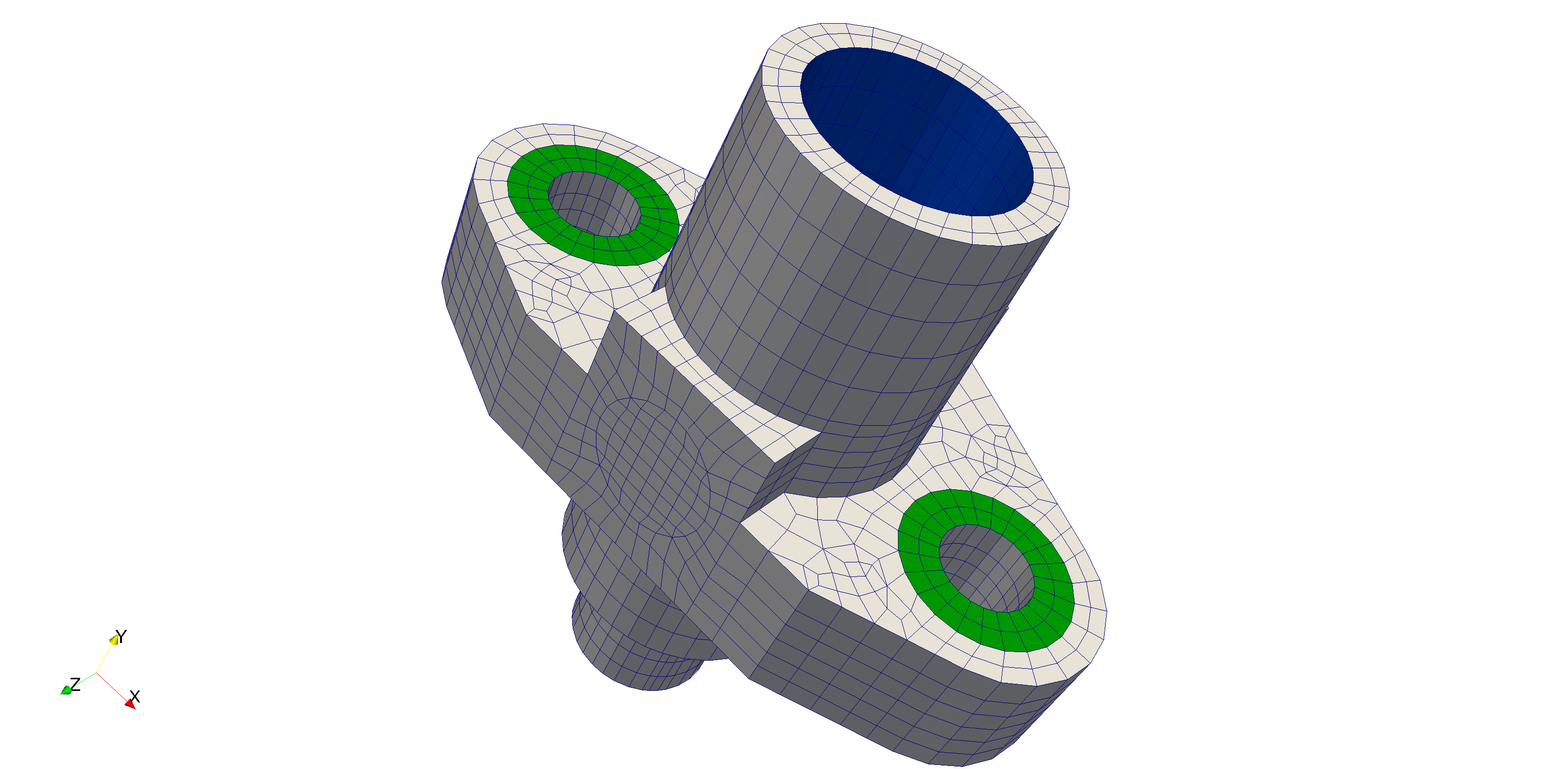

Fig. 2 Mesh of the first case - flange.

Boundary conditions

Next we need to set boundary conditions. Open the file T inside the 0 directory from your local left-hand shell.

code 0/T

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class volScalarField;

13 object T;

14}

15// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

16

17dimensions [0 0 0 1 0 0 0];

18

19internalField uniform 273;

20

21boundaryField

22{

23 patch1

24 {

25 type zeroGradient;

26 }

27

28 patch2

29 {

30 type fixedValue;

31 value uniform 273;

32 }

33

34 patch3

35 {

36 type zeroGradient;

37 }

38

39 patch4

40 {

41 type fixedValue;

42 value uniform 573;

43 }

44}

45

46// ************************************************************************* //

Notice how boundary conditions are set to parts of the mesh that have an identifier like patch2. Those identifiers are defined during the meshing procedure. Here they were defined in the ansys file.

Units are set by the dimensions keyword. The entries refer to the standard SI units [Kg m s K mol A cd]. By having a “1” in the fourth columns, the units of the defined properties has units of Kelvin.

Transport properties

Next we need to set the value of the thermal diffusivity.

code constant/transportProperties

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class dictionary;

13 location "constant";

14 object transportProperties;

15}

16// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

17

18DT DT [0 2 -1 0 0 0 0] 4e-05;

19

20

21// ************************************************************************* //

Again, check that you understand the units, which here add up to m^2/s.

Case control

Finally, we need to set some control parameters like the time step, run time, output writing. These kind of parameters are set in system/controlDict. Open it and explore the values

code system/controlDict

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class dictionary;

13 location "system";

14 object controlDict;

15}

16// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

17

18application laplacianFoam;

19

20startFrom latestTime;

21

22startTime 0;

23

24stopAt endTime;

25

26endTime 3;

27

28deltaT 0.005;

29

30writeControl runTime;

31

32writeInterval 0.1;

33

34purgeWrite 0;

35

36writeFormat ascii;

37

38writePrecision 6;

39

40writeCompression off;

41

42timeFormat general;

43

44timePrecision 6;

45

46runTimeModifiable true;

You can find detailed descriptions of the different parameters in the OpenFoam User Guide. Note that the solver we are using is called laplacianFoam.

Running the case

Now we are finally ready to run our first test case. Just type this into your docker shell:

laplacianFoam

Notice how several directories are appearing, which contain the intermediate results. You can postprocess the case by simply opening the a.foam file from paraview.