Flow on the pore scale

Digital Rock Physics - Effective Permeability of Rocks

We will start by exploring concepts of Digital Rock Physics (DRP) and how to compute the effective permeability of a porous rock sample from direct numerical simulations of flow on the pore scale. One way is to scan (e.g. using cT) a rock sample, segment the pore space, and then perform direct numerical simulations of flow through the pore space. From the resulting flow field, we can compute the effective permeability of the sample. This effective permeability can then be used in larger-scale continuum simulations of flow in porous media using Darcy’s law. Have a look at the digital porous media portal to get a better idea of what Digital Rock Physics is all about!

We will start by making a direct simulation of flow on the pore level and post-process it for extracting the effective permeability.

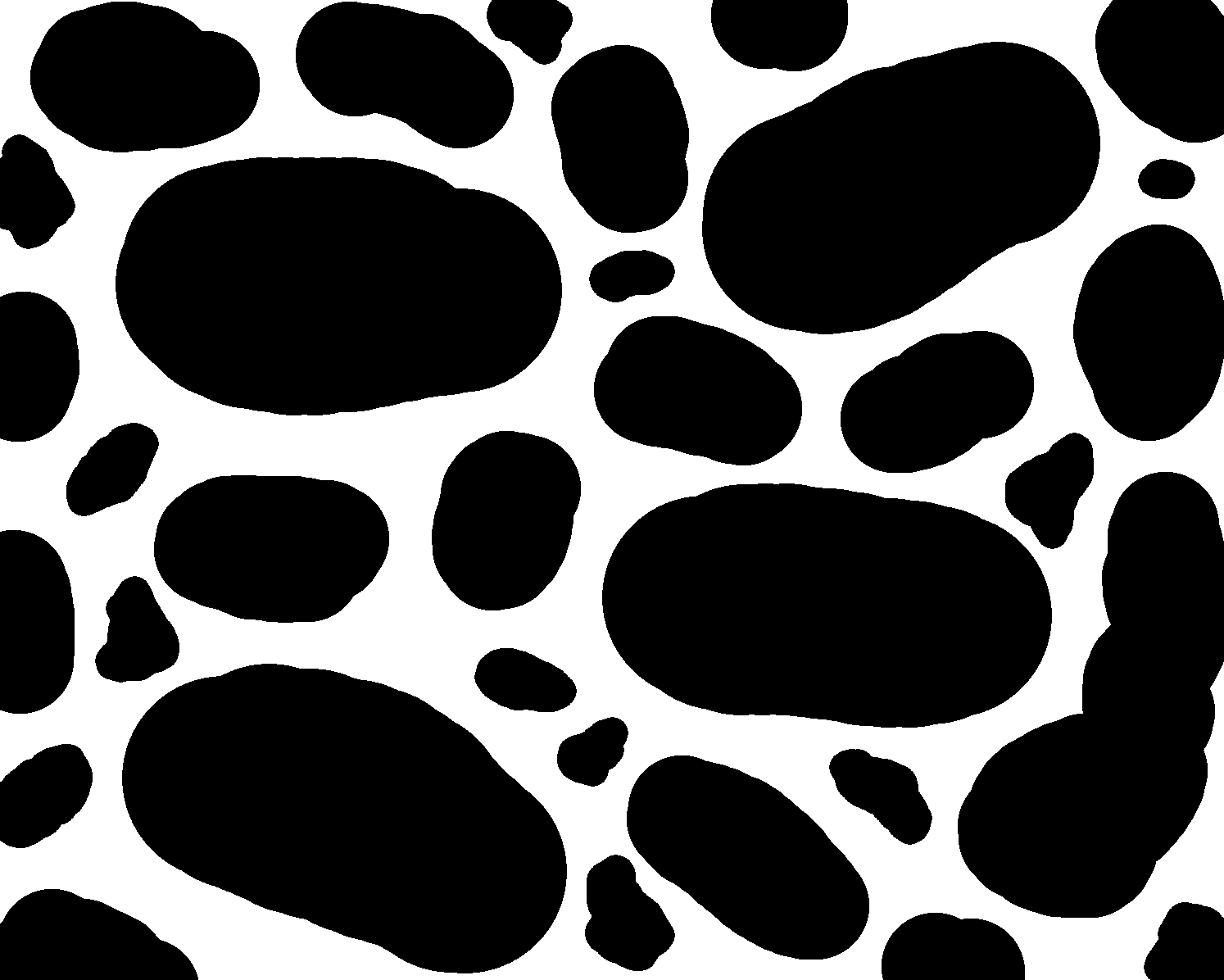

Fig. 6 Synthetic image of the pore geometry. Pores are white; solids are black.

To compute permeability, we will apply constant pressure boundary conditions and evaluate the flow rate through the sample. Once we have that, we can re-arrange Darcy’s law to solve for permeability:

Ok, let’s do it!

Mesh generation

The first major step is to generate a mesh of the pore space (Fig. 6). For this purpose, we will use OpenFOAM’s snappyHexMesh tool. It allows meshing arbitrary and complex geometries and is very powerful. Unfortunately, it can also be infuriating to use as it asks for many user-defined parameters and can be quite picky about the choices made.

Tip

We will not go into the details of snappyHexMesh (SHM) works. If you want to use and/or understand it, a good starting point is the user guide linked above. Another great resource is the Rock Vapor Classic tutorial series.

In a nutshell, snappyHexMesh (SHM) is about starting from a blockMesh (as in the previous lecture), cutting out the solid grain (described by a triangulated surface), and then snapping the mesh to this surface. A typical way to describe this surface is an .stl file - a file format for triangulated surfaces that is often used for 3D printing.

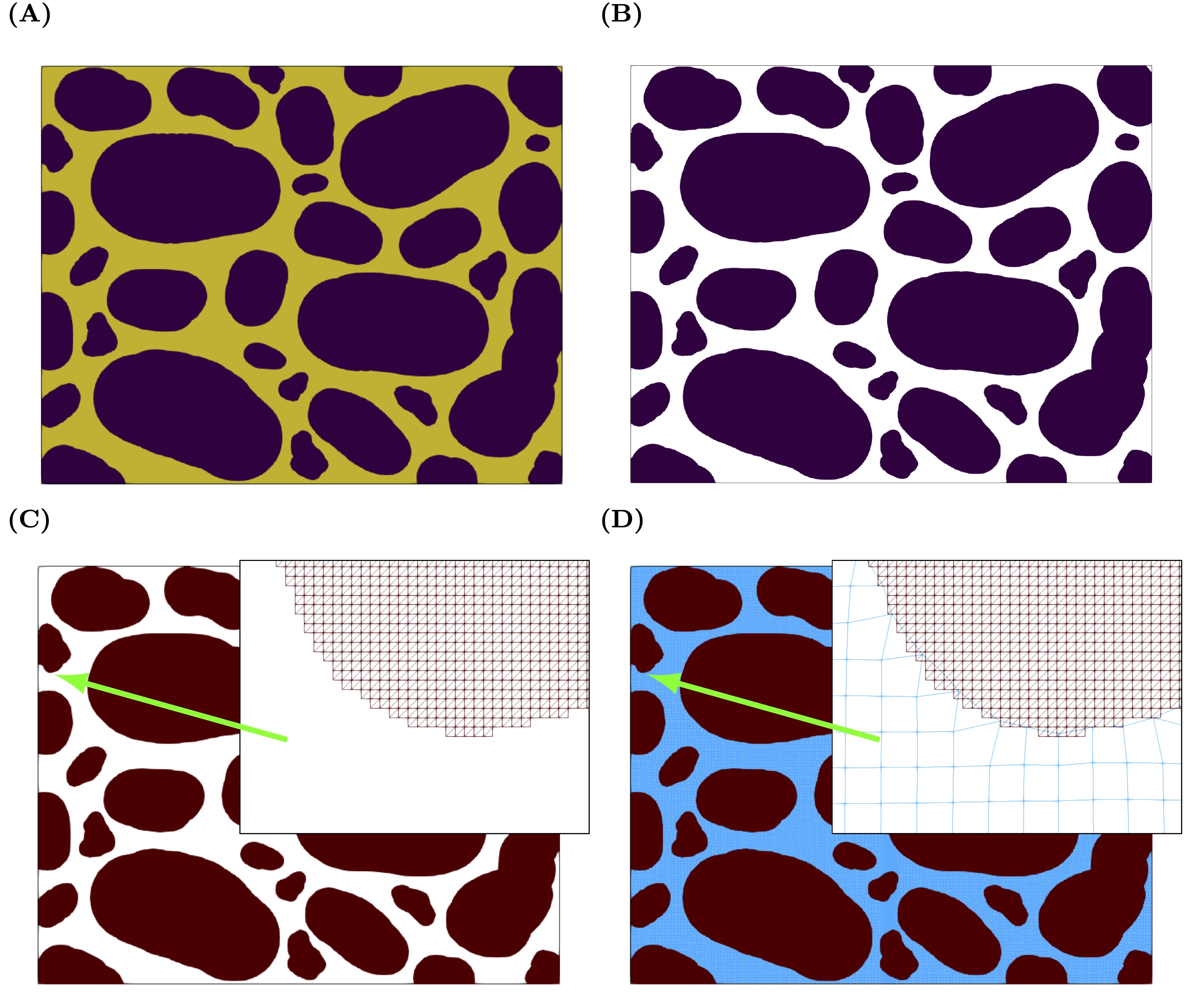

Fig. 7 Workflow illustrating the meshing process.

The steps involved are shown in Fig. 7 . Starting from an image, an stl file is created that is then used during the meshing process. Most of the steps will rely on paraview filters and the workflow is this.

Start with an image (A).

Save it as a .vti file that is easily understood by Paraview. We use porespy for this step.

Load the vti file into paraview and use the clip (B) and triangulation (B) filers to created a surface of the pore space (C).

Save this surface as a stl file

Python pre-processing

Let’s work through the steps involved and assume we received a 2-D image of scanned pore space ( Fig. 7 A). We need to translate it into something that Paraview understands, so that we can do the segmentation and surface generation. We will use porespy for it; make sure it is available in your pyhton environment.

The complete openFOAM case can be downloaded from here .

Copy the case into your shared working directory (probably $HOME/HydrothermalFoam_runs). You need to do this within the docker container (your right-hand shell in Visual Studio Code if you followed the recommended setup).

Check out the directory structure shown in Listing 6.

.

├── 0

│ ├── U

│ └── p

├── a.foam

├── clean.sh

├── constant

│ ├── transportProperties

│ ├── triSurface

│ │ └── porous_model.stl

│ └── turbulenceProperties

├── geometry

│ └── porousModel.png

├── run.sh

└── system

├── blockMeshDict

├── changeDictionaryDict

├── controlDict

├── extrudeMeshDict

├── fvSchemes

├── fvSolution

├── meshQualityDict

└── snappyHexMeshDict

Tip

Most OpenFoam cases include scripts like run.sh and clean.sh. The run.sh script is a good starting point for “understanding” a case. It lists all commands that have to be executed (e.g. meshing, setting of properties, etc.) to run a case. The clean.sh script cleans up the case and deletes e.g. the mesh and all output directories. Have a look into these files and see if you understand them!

Next we import the .png file from the geometry folder and convert it to a .vti file, which is the Visualization Toolkit’s format for storing image data. Note that vti files can also store series of images, which is important when doing this in 3-D.

import numpy as np

from PIL import Image

import porespy as ps

import os

impath = './geometry' # image path

imname = 'porousModel.png' # file name

# 1. use PIL to load the image

# convert("L") converts RGB into greyscale, L = R * 299/1000 + G * 587/1000 + B * 114/1000

image = Image.open(os.path.join(impath, imname)).convert("L")

# 2. convert image into numpy array with "normal" integer values

arr = np.asarray(image, dtype=int)

# 3. save as vti (VTK's image format)

# 3.1 make 3D by repeating in new axis=2 dimension (openfoam and porespy want 3D)

arr_stacked = np.stack((arr,arr), axis=2)

# 3.2 save as vti using porespy

ps.io.to_vtk(arr_stacked, 'geometry/porous_model')

You can put this little script into a jupyter notebook or save it as .py (e.g. png2vti.py), then activate the right kernel (e.g. conda activate py312_dome_workshop), and do this:

python png2vti.py

After running it, you should have a file porous_model.vti in the geometry folder.

Tip

If you are interested in the vti file format, this is what we have just written to porous_model.vti. There is a non-zero chance that porespy will write out a binary file and not ascii. If that is the case, you can open it in paraview.

<VTKFile type="ImageData" version="1.0" byte_order="LittleEndian" header_type="UInt64">

<ImageData WholeExtent="0 1196 0 1494 0 2" Origin="0 0 0" Spacing="1 1 1" Direction="1 0 0 0 1 0 0 0 1">

<Piece Extent="0 1196 0 1494 0 2">

<PointData>

</PointData>

<CellData Scalars="im">

<DataArray type="Int64" Name="im" format="ascii" RangeMin="0" RangeMax="255">

255 255 255 255 255 255

255 255 255 255 255 255

255 255 255 255 255 255

...

Notice how this is written as cell data. The total extents are 1197x1495x3, the voxel size is 1, and the cell data is 1196x1494x2 (our two images).

Now comes the segmentation and triangulation part to make an stl file that openFOAM understands. We will use paraview for this and there are different ways of doing this:

use paraview’s graphical user interface

use paraview’s inbuild python shell

install paraview into a conda environment and do everything in python scripts or notebooks (the paraview python bindings are called

paraview.simplebut are sometimes a pain to install).

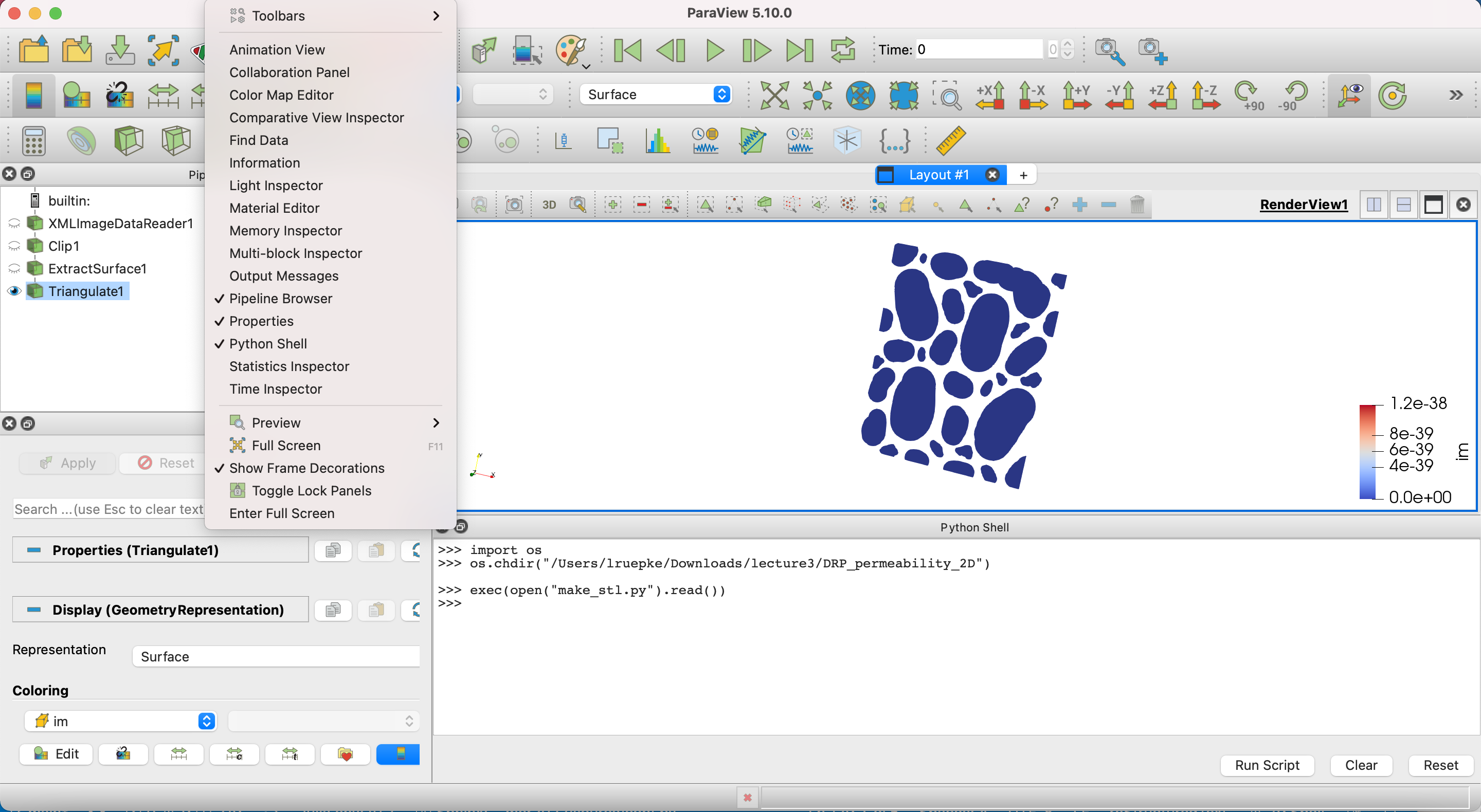

Fig. 8 Using the paraview python shell.

Here is some python code that uses the paraview python bindings. You can save it into your case directory. Or, you use the paraview GUI to create the stl file.

# workflow as python code using the paraview.simple module

# from paraview.simple import * #not needed in paraview's python shell

import os

def write_stl(vti_file, stl_file):

# 1. load vti file

data = OpenDataFile(vti_file)

# 2. clip at some intermediate value (we have 0 and 255 as pores and grains)

clip1 = Clip(data, ClipType = 'Scalar', Scalars = ['CELLS', 'im'], Value = 127.5, Invert = 1)

# 3. make a surface of the remaining grains

extractSurface1 = ExtractSurface(clip1)

# 4. and triangulate it for stl export

triangulate1 = Triangulate(extractSurface1)

# 5. finally save it as an stl file

SaveData(stl_file, proxy = triangulate1)

# main part

vti_file = './geometry/porous_model.vti' # input .vti file

stl_file = './constant/triSurface/porous_model.stl' # output .stl file

# call function

write_stl(vti_file, stl_file)

An easy way to exectute the python scrip is to save the above code into a file (e.g. write_stl.py) and call it from the python shell in paraview Fig. 8. Within the shell, you first make sure that you are in your case directory; then you make the correct folder to hold the .stl file that we will create (./constant/triSurface).

import os

os.chdir("your_case_directory")

os.mkdir('constant/triSurface')

exec(open("your_file_name.py").read())

This will create a .stl file, which we will use in the meshing process.

If you did not use the python script but did everything step-by-step using the paraview GUI, you might have to do some cleanup, so that the files are in the correct location. Move the vti file into ./geometry and the stl file into ./constant/triSurface, where openFOAM expects it. This assumes that you are in the case directory.

mv ./porous_model.vti ./geometry/

mv ./porous_model.stl ./constant/triSurface/

OpenFOAM case

Making the mesh

Great, back to openfoam for the final mesh making! Making the mesh with SHM is a two-step process. First we make a standard blockMesh background mesh. This is, as usual, controlled by system/blockMeshDict:

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class dictionary;

13 object blockMeshDict;

14}

15

16// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

17

18convertToMeters 1;

19

20lx0 0;

21ly0 0;

22lz0 0;

23

24lx1 1196;

25ly1 1494;

26lz1 1;

27

28vertices

29(

30 ($lx0 $ly0 $lz0) //0

31 ($lx1 $ly0 $lz0) //1

32 ($lx1 $ly1 $lz0) //2

33 ($lx0 $ly1 $lz0) //3

34 ($lx0 $ly0 $lz1) //4

35 ($lx1 $ly0 $lz1) //5

36 ($lx1 $ly1 $lz1) //6

37 ($lx0 $ly1 $lz1) //7

38);

39

40blocks

41(

42 hex (0 1 2 3 4 5 6 7) (315 390 1) simpleGrading (1 1 1)

43);

44

45edges

46(

47);

48

49boundary

50(

51 top

52 {

53 type symmetryPlane;

54 faces

55 (

56 (7 6 3 2)

57 );

58 }

59

60 inlet

61 {

62 type wall;

63 faces

64 (

65 (0 4 7 3)

66 );

67 }

68

69 bottom

70 {

71 type symmetryPlane;

72 faces

73 (

74 (1 5 4 0)

75 );

76 }

77

78 outlet

79 {

80 type patch;

81 faces

82 (

83 (1 2 6 5)

84 );

85 }

86

87 front

88 {

89 type patch;

90 faces

91 (

92 (0 3 2 1)

93 );

94 }

95 back

96 {

97 type patch;

98 faces

99 (

100 (4 5 6 7)

101 );

102 }

103);

Notice how we set the vertical and horizontal extents to 1196 and 1494, which is the pixel resolution of the image. We will scale it later to physical dimensions. Note how this is actually a 3D mesh, with one cell in the third dimension.

Now have a look at system/snappyHexMeshDict. We will not go into details here, just explore the general structure yourself if you are interested using the resources linked above.

Time to make the mesh! Run each of the steps below individually and check out the results in paraview.

blockMesh

snappyHexMesh -overwrite

Create a temporary file a.foam to load the case into paraview. Also load the stl file to see how well the mesh fits the geometry.

Now we need to make the mesh 2D again for our simulation. This is done by taking the front surface of the 3D mesh and extruding it. Afterwards, we need to set the front and back surface to empty, so that the mesh is truly 2D. This is a bit of a hack, but snappyHexMesh does not do 2D meshes directly.

extrudeMesh

changeDictionaryDict

Both commands read the respective dictionary files from system. The first command extrudes the front surface of the mesh by 1 cell in the z-direction. The second command changes the front and back patches to empty.

Finally, we need to scale the mesh to physical dimensions. We will assume that each pixel in the image is 1 micrometer (\(10^{-6} m\)). This is done using the transformPoints utility.

transformPoints "scale=(1e-6 1e-6 1e-6)"

Boundary conditions

Next we need to set boundary conditions. Our “rock” sample is 1196 and 1494 \(\mu m\) and we will apply a constant pressure drop of 1 Pa. We will further use openFOAM’s simpleFoam solver, which resolves incompressible steady-state flow. One important thing to remember is that openFOAM uses the kinematic pressure in incompressible simulations, which is the pressure divided by density. If we assume that water with a density of \(1000kg/m^3\) is flowing through our example, we will need to set a constant pressure value of \(P_{left}=0.001 m^2/s^2\). The pressure on the right-hand side will be set to zero.

Open the file p inside the 0 directory from your local left-hand shell.

code 0/p

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class volScalarField;

13 location "0";

14 object p;

15}

16// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

17

18dimensions [0 2 -2 0 0 0 0];

19

20internalField uniform 0;

21

22boundaryField

23{

24 top

25 {

26 type symmetryPlane;

27 }

28 inlet

29 {

30 type fixedValue;

31 value uniform 0.001;

32 }

33 bottom

34 {

35 type symmetryPlane;

36 }

37 outlet

38 {

39 type fixedValue;

40 value uniform 0;

41 }

42 solids

43 {

44 type zeroGradient;

45 }

46 frontAndBack

47 front

48 {

49 type empty;

50 }

51 back

52 {

53 type empty;

54 }

55}

The boundary conditions are again set for the patches that were defined in the blockMeshDict. Notice how the sides have constant values. The top and bottom are symmetry planes and the internal boundaries with the solid grains get a zeroGradient condition. As we are performing a 2-D simulations, the front and back faces are set to empty.

Remember that units are set by the dimensions keyword. The entries refer to the standard SI units [Kg m s K mol A cd]. By having a 2 in the second and third column, we get the correct units for the kinematic pressure.

We also need to set boundary conditions for the velocity.

code 0/U

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class volVectorField;

13 location "0";

14 object U;

15}

16// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

17

18dimensions [0 1 -1 0 0 0 0];

19

20internalField uniform (0 0 0);

21

22boundaryField

23{

24 top

25 {

26 type symmetryPlane;

27 }

28 inlet

29 {

30 type zeroGradient;

31 }

32 bottom

33 {

34 type symmetryPlane;

35 }

36 outlet

37 {

38 type zeroGradient;

39 }

40 solids

41 {

42 type noSlip;

43 }

44 front

45 {

46 type empty;

47 }

48 back

49 {

50 type empty;

51 }

52}

The top and bottom are again symmetry planes and the zeroGradient condition ensure that fluids can freely flow in and out. The contacts with the solid grains get noSlip, which makes the velocity go to zero; front and back are again set to empty.

Transport properties

Final step is to set the remaining free parameter (viscosity) in equation ().

code constant/transportProperties

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class dictionary;

13 object transportProperties;

14}

15// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

16

17transportModel Newtonian;

18

19nu [0 2 -1 0 0 0 0] 1e-06;

20

21// ************************************************************************* //

Again, in incompressible simulations (where we can divide the momentum balance equation by density) the kinematic viscosity is used, which has units of \(m^2/s\). The value of \(1e{-6} m^2/s\) with an assumed density of \(1000kg/m^3\) is \(1 mPa\) - a typical value for water at room temperature.

Case control

Finally, we need to set some control parameters in system/controlDict. Open it and explore the values.

code system/controlDict

1/*--------------------------------*- C++ -*----------------------------------*\

2========= |

3\\ / F ield | OpenFOAM: The Open Source CFD Toolbox

4 \\ / O peration | Website: https://openfoam.org

5 \\ / A nd | Version: 7

6 \\/ M anipulation |

7\*---------------------------------------------------------------------------*/

8FoamFile

9{

10 version 2.0;

11 format ascii;

12 class dictionary;

13 object controlDict;

14}

15// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

16

17application simpleFoam;

18

19startFrom startTime;

20

21startTime 0;

22

23stopAt endTime;

24

25endTime 1500;

26

27deltaT 1;

28

29writeControl timeStep;

30

31writeInterval 1500;

32

33purgeWrite 0;

34

35writeFormat ascii;

36

37writePrecision 9;

38

39writeCompression off;

40

41timeFormat general;

42

43timePrecision 6;

44

45runTimeModifiable true;

The solver is a stead-state solver, so that the settings are quite simple with respect to transient simulations.

Running the case

Now we are finally ready to run the case! Just type this into your docker shell:

./run.sh

or, if you did the steps above by hand:

simpleFoam

Notice how one new directory is appearing, which contains the steady-state solution. Check that the solution has converged by looking at the log.simpleFoam file.

tail -15 tail -15 log.simpleFoam

Time = 536s

smoothSolver: Solving for Ux, Initial residual = 8.33332294e-10, Final residual = 8.33332294e-10, No Iterations 0

smoothSolver: Solving for Uy, Initial residual = 9.84562833e-10, Final residual = 9.84562833e-10, No Iterations 0

GAMG: Solving for p, Initial residual = 9.67603673e-09, Final residual = 9.67603673e-09, No Iterations 0

time step continuity errors : sum local = 7.10016507e-07, global = -1.23478036e-07, cumulative = 4.09450688

ExecutionTime = 24.158663 s ClockTime = 25 s

SIMPLE solution converged in 536 iterations

End

And explore the solution in Paraview!

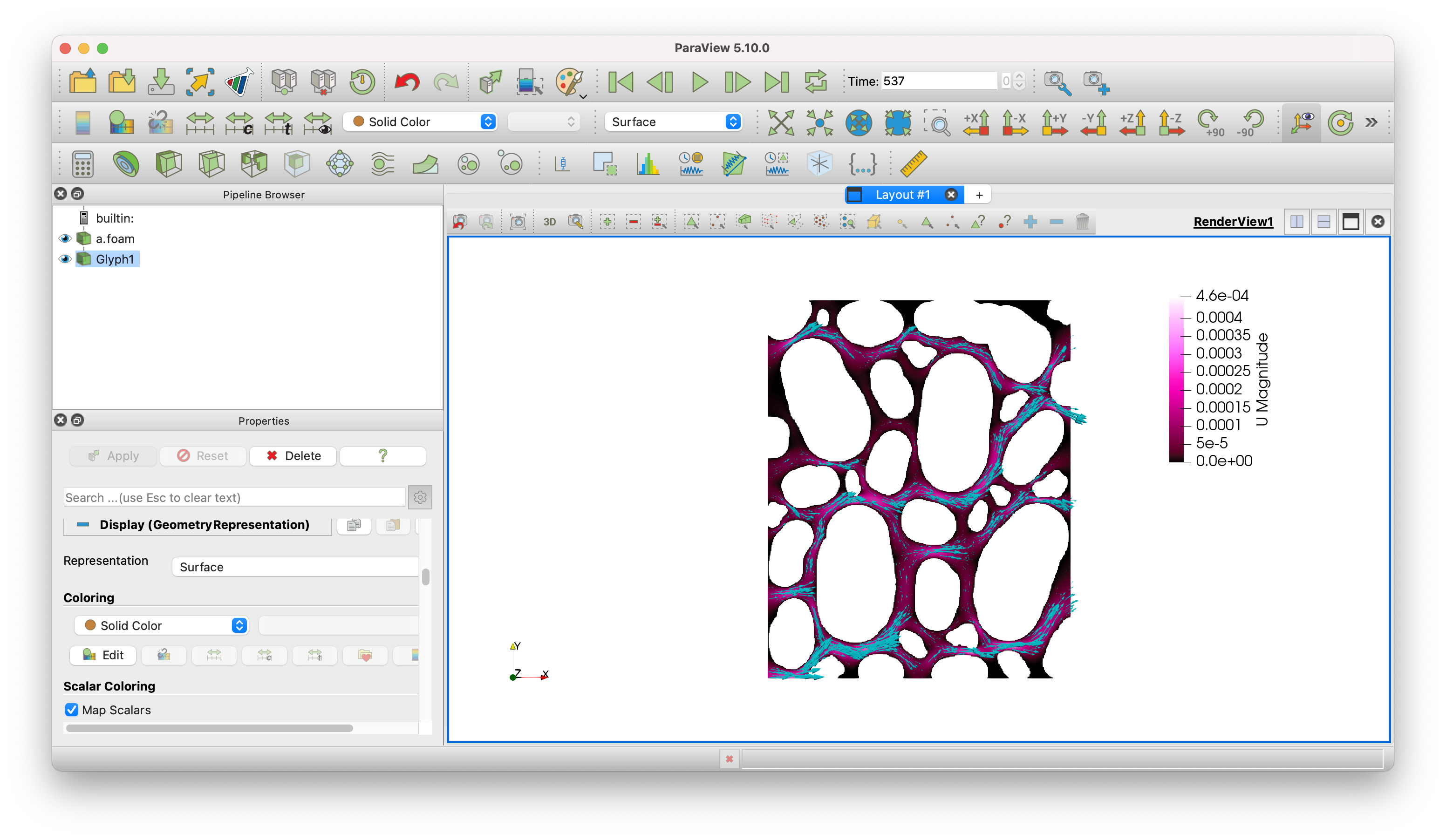

Fig. 9 Predicted velocity field.

Post-processing / Effective permeability

Time to get back to our initial objective. What is the predicted permeability of our sample? We need to postprocess our solution and solve equation (), which requires are few intermediate steps. First, we need to compute the cell volumes, so that we can integrate the velocity over the total volume. Here comes openFOAM’s postProcess functionality handy. Just do this:

postProcess -func writeCellVolumes

This will create a new variable \(V\) in in the output directories, which is the volume of each cell. Next we can save the full solution as a vtk file, so that we can postprocess it with python.

foamToVTK -useTimeName -latestTime -poly

Check that a new VTK directory was created. Now we are ready for some more fancy post-processing using python.

Here is an example script for computing permeability. You can turn it into a jupyter notebook or save it as a .py file into your case directory and run it from there.

import vtk

import numpy as np

from vtk.util import numpy_support as VN

import matplotlib.pyplot as plt

# load VTK data

vtkFile = 'VTK/DRP_permeability_2D_536.vtk'

reader = vtk.vtkUnstructuredGridReader()

reader.SetFileName(vtkFile)

reader.ReadAllScalarsOn()

reader.ReadAllVectorsOn()

reader.Update()

data = reader.GetOutput()

# extract velocity arrays

Vcells = VN.vtk_to_numpy(data.GetCellData().GetArray('V'))

U = VN.vtk_to_numpy(data.GetCellData().GetArray('U'))

Umag = np.sqrt(U[:,0]**2+U[:,1]**2+U[:,2]**2)

Ux = U[:,0]

Uy = U[:,1]

Uz = U[:,2]

# calculate volume fluxes

qx = []

qy = []

for c in range(len(Vcells)):

q1 = Vcells[c] * Ux[c]

q2 = Vcells[c] * Uy[c]

qx.append(q1)

qy.append(q2)

# simulation parameters

DP = 1 # pressure drop [Pa]

nu = 1e-06 # kinematic viscosity [m²/s²]

rho = 1000 # density [kg/m³]

mu = nu * rho # dynamic viscosity [kg/(m*s)]

dx = 0.001196 # model length x [m]

dy = 0.001494 # model width y [m]

dz = 1e-6 # model thickness z [m]

A = dy * dz

V = dx * A

# calculate Darcy velocity

U_Darcy_x = np.sum(qx)/V

kxx = mu * dx * U_Darcy_x/DP

print('Bulk permeability: %5.3e m2' % kxx)

We made it! \(2.71e^{-11} m^2\) is our predicted effective permeability of our sample.